骨是一种典型的脆性材料,脆性材料一旦发生破坏,结构的承载能力会大幅降低。日常生活中,颅骨骨折是常见的头部损伤,并常与外伤性脑损伤联系在一起。颅脑损伤多见于交通事故、高处坠落、房屋倒塌、弹片击伤、爆炸冲击等场合,在人体各处损伤中,其发生的概率为10%~20%[1]。由密质骨和松质骨构成的头盖骨轻质多孔结构能够吸收外界能量,可抵御一定范围的冲击载荷,点阵夹芯结构的设计思想也是受到了头骨构型的启发[2]。密质骨与松质骨的基本组分相同,区别在于孔隙率与组织形态。骨头中存在两种类型的材料属性。密质骨的强韧性较松质骨强20倍,密质骨在破坏前受到较大应力较小应变。松质骨在失效前能承受75%的应变,而密质骨承受多于2%的应变即发生破坏。由于松质骨自身多孔特性,存储包括血液、骨髓及体液等液体,松质骨与密质骨相比有较强的储能能力。描述骨头力学特性的三个重要参数包括极限载荷、极限变形及储能大小。极限载荷受加载类型及加载速率的影响。极限形变同加载速率及加载方向有关。针对骨材料的储能大小,儿童骨头的吸能特性较成人相比更优越。当传递给骨头的能量大于骨头能吸收的能量,破坏即将发生。本文以二维头盖骨截面受冲击物作用为例,阐释头盖骨能量吸收的原理,从科普角度阐述原有的学术研究成果[3]。对头盖骨抗冲击性能的深入认识将有助于预防颅骨骨折的发生和头部防护结构的设计。

1 脆性材料与韧性材料

工程构件在断裂前发生明显的塑性变形,称为韧性断裂;断裂前不发生或只有少量宏观塑性变形,则为脆性断裂。脆性是指当外力达到一定限度时,材料发生无先兆的突然破坏,且破坏时无明显塑性变形的性质。图1给出脆性和韧性材料受拉伸载荷作用下的断裂形貌示意图及两种材料的工程应力-应变曲线。曲线下的面积表示材料在断裂前吸收的能量,或断裂材料所需的能量。曲线下面积越大,材料抵抗断裂的能力越强。

图1

图2

2 头盖骨冲击数值模型的建立

本文采用的高分辨率三维显微CT系统可真实再现头盖骨试样的内部结构特征,并将扫描数据导入逆向工程软件进行数值模型的重构及网格划分。由于头盖骨自身的多孔特性,孔洞周围易出现应力集中,需要对孔洞周围的网格进行加密,并选用LS-DYNA中的平面单元plane162模拟平面应力问题。鉴于三角形网格可用来模拟复杂物体的表面,本文选用此网格类型对结构进行网格划分。对头盖骨截面对应的数值模型进行了收敛性分析,数值模型达到了局部收敛。头盖骨几何模型的两端保持固支约束,冲击物设定为刚体,冲击头盖骨截面的中间区域。图3给出了头盖骨试样的截面位置及其几何特征。冲击载荷作用下的截面对应的跨距长度为40 mm,截面在冲击位置对应的厚度约为6.83 mm。截面I上孔洞最小长度约为0.09 mm,孔洞最大长度约为3.6 mm。此头盖骨截面的孔隙率约为10.1%。 冲击物的半径为4.5 mm。

图3

3 头盖骨截面的能量吸收

为阐明头盖骨受中低速冲击载荷作用下的能量吸收规律,本文针对截面I,研究冲击速度在2.8$\sim$50 m/s区间内人头盖骨多孔结构的渐进失效行为。阈值速度是指冲击物将要冲出但未能冲出头盖骨的临界速度,截面I对应冲击物的阈值速度是23.2 m/s。由图4可发现,结构内部的孔洞周围易发生破坏。当速度小于阈值速度时,孔洞附近区域易出现应力集中现象。随着冲击速度的减小,孔洞周围的高应力会降低,同时头盖骨截面局部应力集中的程度也会减弱。当高于阈值速度时,以50 m/s为例,冲击物从头盖骨截面穿出,使截面形成一个与冲击物尺寸等大的破坏区域,并伴随小变形及碎片产生。其原因在于结构在较大冲击速度下来不及产生形变。相反,在较小冲击速度作用下,头盖骨获得的能量不能很快得到释放,进而结构内部出现裂纹。具体来讲,裂纹尖端出现在孔洞周围,并沿跨距方向扩展,产生可见的破坏。当冲击物速度为2.8 m/s时,头盖骨截面外侧密质骨发生初始破坏。当冲击速度在7$\sim$20 m/s的范围内,随着冲击速度增加,头盖骨的失效区域逐渐增大。当冲击速度约为23.2 m/s时,头盖骨截面被完全穿透,对应失效区域的长度约为球形冲击物直径的3倍。当冲击速度大于30 m/s时,除了从截面飞出碎片的数量与尺寸不同,不同冲击速度对应的头盖骨截面的冲击渐进失效行为与受冲击影响的区域几乎是相同的。

当冲击速度为23.2 m/s时,头盖骨截面的失效过程如图5所示。图5(a)给出头盖骨截面的密质骨、松质骨能量吸收比随着时间的变化关系;上述四种不同时刻对应的头盖骨截面的失效行为如图 5(b)所示。首先,在冲击物接触头盖骨多孔结构外侧密质骨后(I—II 阶段),结构出现破坏。然后,孔洞附近的应力集中使得头盖骨中心处产生裂纹,直到头盖骨出现破坏。在冲击区域附近的某些小块结构变成碎片,从头盖骨截面飞出(III)。此外,在冲击过程中结构固支约束端部的孔洞附近同样存在应力集中现象,进而引起裂纹产生和扩展。最后,冲击物卡在头盖骨中,并且冲击物与头盖骨的接触区域完全破坏。从头盖骨截面飞出碎片,带走大量的能量(IV)。由于松质骨多孔且变形区域大,大部分冲击能量被松质骨吸收;相反,由于密质骨孔洞少,接近实体且厚度小,截面中密质骨部分仅吸收小部分能量。

图4

图5

头盖骨多孔结构在不同冲击速度下的能量吸收能力如图6所示。图中,$E_{\rm c}$和$E_{\rm s}$分别表示头盖骨中密质骨和松质骨的能量吸收;$E_{\rm k}$表示冲击物的动能变化,$E_{\rm T}$表示冲击物阈值速度对应的头盖骨的能量吸收,即冲透阈值能量。基于能量守恒,系统总能量可分为两部分

其中,${E}_{\text{abs}}$表示头盖骨截面的能量吸收,即冲击物的初末动能改变量;${E}_{\rm d}$表示由头盖骨破坏造成的截面能量耗散;$m_\text{i} $表示冲击物的质量;$V_{\rm in}$表示冲击物的初始速度;$m_{\rm d}$表示由穿透引起的碎片质量;$V_{\rm i\text{out}}$和$V_{\text{dout}}$分别是冲击物和碎片的剩余速度。${E}_{\text{abs}}$包含${E}_{\rm d}$和由冲击造成的碎片动能两部分。密质骨和松质骨部分的能量吸收可用于计算整体的吸能量${E}_{\text{abs}}$。

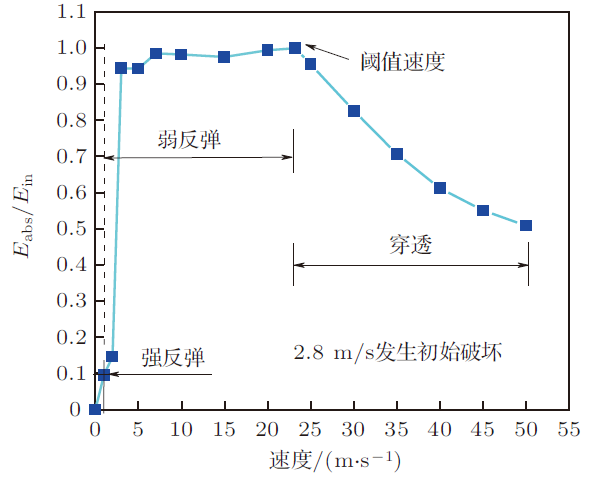

本文采用无量纲参数$E_{\text{abs}}/E_\text{T}$表示头盖骨截面的能量吸收能力。图6给出了能量吸收能力随着冲击速度的变化曲线。曲线分为两阶段:第一阶段表示冲击物的反弹,第二阶段表示冲击物的穿透,两阶段交点对应的横坐标表示冲击阈值速度。如图6所示,头盖骨的能量吸收能力随着冲击速度的增加而变大。阈值速度对应单位厚度截面I吸收的能量为0.134 J。用无量纲参数$E_{\rm abs}/E_{\text{in}}$表示头盖骨截面的吸能率。图7建立了结构吸能率与冲击速度之间的关系。当冲击物以阈值速度冲击头盖骨时,结构吸能率接近1,意味着此刻冲击物的动能被全部吸收。此曲线分为冲击物的强反弹、弱反弹和穿透三个阶段。强反弹表示结构依靠弹性变形吸收冲击物的动能,使得大部分能量被反弹。弱反弹表示仅有少量能量被反弹,而大部分能量被头盖骨截面吸收。穿透表示部分能量由冲击物引起的碎片吸收,剩余能量则被截面吸收。对于冲击速度大于23.2 m/s 的情况,结构吸能率随着冲击速度的增加而减小。这意味着冲击物的初始动能随着冲击速度增加而增大;然而,头盖骨截面可存储的能量是定值,飞出碎片的动能使得吸能量进一步增加。与头盖骨截面吸收的能量相比,被碎片带走的能量较小,因此结构吸能率在第三阶段呈现下降趋势。

图6

图7

4 总结

采用数值模拟方法对二维头盖骨截面在中低速冲击作用下的失效机制和能量吸收进行了研究。头盖骨是一种脆性材料,其内部孔洞周围的应力集中致使裂纹的产生与扩展,单位厚度头盖骨截面吸收的能量约为0.134 J。可以发现:对于给定的冲击能量,截面中的松质骨疏松多孔且具有较大的变形区域,大部分冲击能量被松质骨吸收;相反,密质骨孔洞少,接近实体且厚度小,截面中密质骨部分仅吸收小部分能量。头部防护结构的设计依赖于头盖骨吸收的能量大小,同时,探究人头盖骨能量吸收的奥秘有助于人们对头盖骨力学性能的深层次认识。

参考文献

颅骨三维模型的建立和有限元计算及实验应力分析的研究. [博士论文]

Research on establishment and finite element calculation of three-dimensional skull model and experimental stress analysis. [PhD Thesis]

新型复合材料点阵结构的研究进展

Progresses in the study on novel composite sandwich panels with lattice truss cores

Impact response and energy absorption of human skull cellular bones

Head injury prediction tool for predictive systems optimization.

Development of a human body finite element model for restraint system R&D applications

The mechanical properties of trabecular bone: dependence on anatomic location and function

In 1961, Evans and King documented the mechanical properties of trabecular bone from multiple locations in the proximal human femur. Since this time, many investigators have cataloged the distribution of trabecular bone material properties from multiple locations within the human skeleton to include femur, tibia, humerus, radius, vertebral bodies, and iliac crest. The results of these studies have revealed tremendous variations in material properties and anisotropy. These variations have been attributed to functional remodeling as dictated by Wolff's Law. Both linear and power functions have been found to explain the relationship between trabecular bone density and material properties. Recent studies have re-emphasized the need to accurately quantify trabecular bone architecture proposing several algorithms capable of determining the anisotropy, connectivity and morphology of the bone. These past studies, as well as continuing work, have significantly increased the accuracy of analytical and experimental models investigating bone, and bone/implant interfaces as well as enhanced our perspective towards understanding the factors which may influence bone formation or resorption.

Prediction of strength and strain of the proximal femur by a CT-based finite element method

AbstractHip fractures are the most serious complication of osteoporosis and have been recognized as a major public health problem. In elderly persons, hip fractures occur as a result of increased fragility of the proximal femur due to osteoporosis. It is essential to precisely quantify the strength of the proximal femur in order to estimate the fracture risk and plan preventive interventions. CT-based finite element analysis could possibly achieve precise assessment of the strength of the proximal femur. The purpose of this study was to create a simulation model that could accurately predict the strength and surface strains of the proximal femur using a CT-based finite element method and to verify the accuracy of our model by load testing using fresh frozen cadaver specimens. Eleven right femora were collected. The axial CT scans of the proximal femora were obtained with a calibration phantom, from which the 3D finite element models were constructed. Materially nonlinear finite element analyses were performed. The yield and fracture loads were calculated, while the sites where elements failed and the distributions of the principal strains were determined.The strain gauges were attached to the proximal femoral surfaces. A quasi-static compression test of each femur was conducted. The yield loads, fracture loads and principal strains of the prediction significantly correlated with those measured (r=0.941, 0.979, 0.963). Finite element analysis showed that the solid elements and shell elements in undergoing compressive failure were at the same subcapital region as the experimental fracture site.]]>

Material properties of human rib cortical bone from dynamic tension coupon testing

The purpose of this study was to quantify both the tensile material properties and structural response of human ribs in order to determine which variables contribute to regional variation in the strength of human ribs. This was done by performing 94 matched tests on human rib specimens; 46 tension coupon tests, 48 three-point bending tests. Contralateral matched specimens were dissected from anterior and lateral regions of ribs 4 through 7 of six male fresh frozen post mortem human subjects ranging from 42 to 81 years of age. Tension coupons were taken from one side of the thorax, while three-point bending specimens were taken from the opposite side as the tension coupons at corresponding anatomical locations. The results of the tension coupon testing showed that there were no significant differences with respect to region or rib level: ultimate stress (p=0.90; p=0.53), ultimate strain (p=0.49; p=0.86), or modulus (p=0.72; p=0.81). In contrast, lateral three-point bending specimens were found to have a significantly higher peak bending moment (p<0.01), peak strain (p=0.03), modulus (p=0.05), and stiffness (p<0.01) than anterior specimens. The lateral three-point bending specimens also had a significantly larger area moment of inertia (p<0.01), larger distance to the neutral axis (p<0.01), smaller ratio of distance to the neutral axis to area moment of inertia (p<0.01), larger cortical bone area (p<0.01), and larger radius of gyration (p<0.01) than the anterior specimens. In addition, the peak moment (Ant p=0.20; Lat p=0.02), peak strain (Ant p=0.05; Lat p=0.15), and stiffness (Ant p<0.01; Lat p<0.01) were found to vary significantly with respect to rib level. Similar to anatomical region, the changes in the structural response with respect to rib level were also accompanied by significant changes in geometry. For anterior specimens, distance to the neutral axis (p<0.01), ratio of the distance to the neutral axis to area moment of inertia (p=0.02) and radius of gyration (p=0.04) were found to be significantly different with respect to rib level. For lateral specimens, the area moment of inertia (p<0.01), distance to the neutral axis (p<0.01), ratio of the distance to the neutral axis to area moment of inertia (p<0.01), the cortical bone area (p=0.01), and radius of gyration (p=0.03) were found to be significantly different with respect to rib level. These results clearly illustrate that there is variation in the structural response of human ribs with respect to anatomical region and rib level and this variation is due to changes in local geometry of each rib while the material properties remain constant.