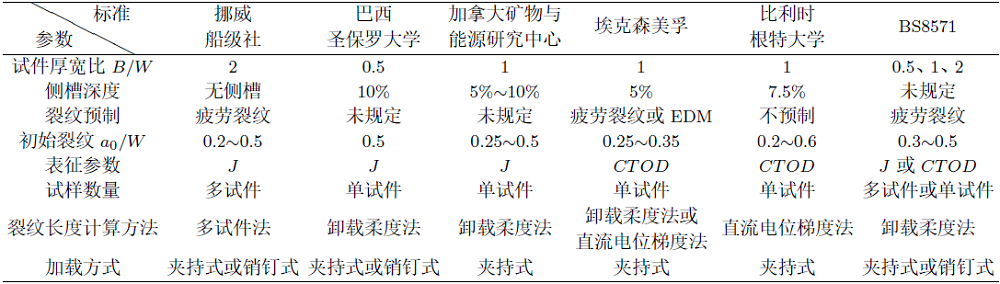

在石油和天然气行业中,通常采用单边缺口拉伸试件(single edge notched tension, SENT)测量管线钢低约束状态下的断裂韧性。该方法在基于应变的设计、工程临界评估以及适用性评价中都得到了广泛应用,大大节省了管道设计和维护成本,促进了管道安全运营技术的发展[5-6]。挪 威船级社、加拿大矿物与能源研究中心[7-8]、埃克森美孚[9]分别针对SENT试件J积分阻力曲线和裂纹尖端张开位 移(crack tip opening displacement, CTOD)阻力曲线提出了三种具有代表性的测试方法,其中DNV方法为多试样法,其余两种为单试样法。英国标准协会在2014年12月发布了首个SENT试件测试标准BS 8571[10]。然而,BS 8571主要是基于DNV-RP-F108提出的,因而具有一定的局限性;美国材料与试验协会开发的SENB和CT试样阻力曲线测试标准ASTM E1820[11]并不适用于SENT试件;我国也尚未发布关于低约束SENT试件断裂韧性的测试标准。

本文对现有SENT试件测试方法进行归纳总结,分析低约束试件常用断裂韧性表征参数的分类与组成,对比阐述测试方法中各关键问题的发展 现状及趋势,总结需要深入研究的内容,为低约束试件断裂韧性测试发展提供一定依据。

1 低约束试件断裂韧性测试发展

SENT试件根据其加载方式和几何特征可分为夹持型和销钉型,通常销钉式SENT试件用于测试管道轴向裂纹,而夹持型SENT试件用于测试管道的环向裂纹。由于环向裂纹是基于应变设计的主要研究问题,因而夹持型SENT试件已成为低约束断裂测试方法的研究热点。

2006年,挪威船级社为评估海底浅裂纹管道的断裂韧性,出版了管道低约束SENT试件断裂韧性测试标准DNV-RP-F108[16]。该标 准采用夹持 型或销钉型SENT试样测试材料的J积分阻力曲线(J-R)。DNV建议试件进行疲劳裂纹预制,预裂纹长度$0.2≤a/W≤0.5$,试件不需要开侧槽,最大裂纹扩展长度为3mm。DNV采用多试样法,要求至少测试6个有效SENT试件。该方法不考虑裂纹扩展修正,因而裂纹扩展较短时,该方法简单实用。考虑焊缝强度匹配和延性裂纹扩展等因素造成的不确定性,该方法在J积分塑性因子的表达式中添加了安全 系数0.85,该安全系数可能导致断裂韧性偏于保守,且测试所需时间与材料成本较大。

2010年,埃克森美孚公司提出了一种使用双应变规测量单个试件CTOD阻力曲线(CTOD-R)的方法[9]。 该方法建议对试件进行疲劳裂纹预制或 使用直径不大于0.15 mm的线切割(electrical discharge machining, EDM)加工,以确保初始长度在$0.25≤ a_{0}/W≤ 0.35$的范围内。EDM可使切口前沿均匀,初始裂纹长度更精确,对于高韧性管线钢和焊缝建议采用,但对于低断裂韧性材料,EDM方法 可能会导致断裂韧性偏高。该方法建议试件侧槽深度占试件厚度的5%。

2 断裂韧性表征参数

2.1 CTOD

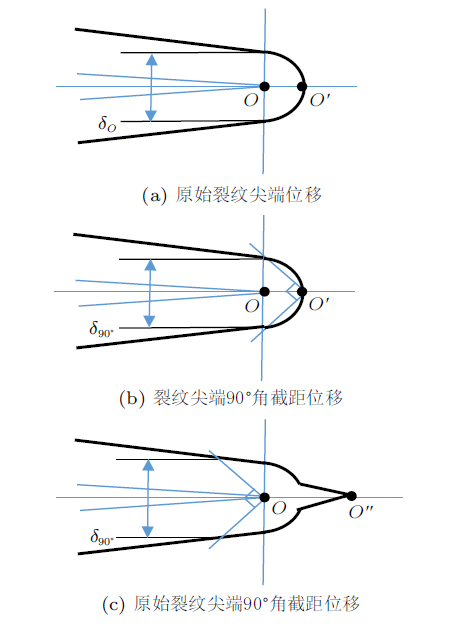

图1

由于局部塑性变形,加载后裂纹尖端钝化。如果加载时,远离裂纹尖端的裂纹表面未变形,只围绕韧带上一点进行刚性旋转,且与初始裂尖处 的钝裂纹前缘相切,则两切点之间的距离即为原始裂纹尖端位移。原始裂纹尖端位移已用于BS 8571[10]和埃克森美孚双应变规方法的CTOD测试中,该CTOD定义与裂纹尺寸和材料硬化响应有关,如果切点位于原始裂纹尖端后,则会高估实际CTOD值。

为了便于在有限元分析中计算裂纹的CTOD,将钝化裂纹尖端开始的两条垂直直线与裂纹表面的截距作为裂纹尖端90° 试件有限元模拟中的便利性,该CTOD定义得到广泛应用,但不适用于扩展裂纹。加拿大矿物与能源研究中心研究J积分 与CTOD转换关系时,采用了此定义计算CTOD。

2.2 J积分

Rice[26]于1967年提出J积分作为表征弹塑性材料裂纹尖端应力应变场的参数。在断裂韧性试验中,可将J积分分为弹性J积分和塑性J积分

分别进行计算,如式(1)所示

式中,$J_{\rm el}$和$J_{\rm pl}$分别表示J积分的弹性分量和塑性分量。

$J_{{\rm el}}$与应力强度因子有关,按式(2)计算

式中,$\nu$是泊松比,$E$是杨氏模量。$K_{\rm I}$为I型裂纹应力强度因子,由载荷和裂纹尺寸通过式(3)确定

式中,$a$为裂纹长度,$W$为试样宽度,$B$为试样厚度,$P$为载荷,$f(a/W)$为几何因子。

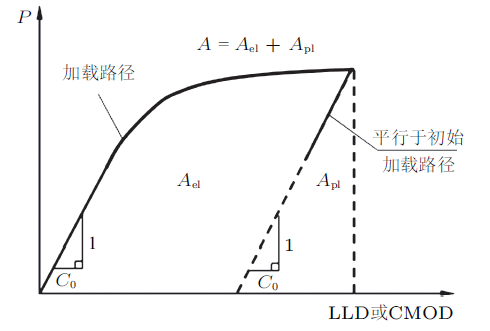

$J$积分的塑性分量可通过引入塑性因子($\eta$)与载荷位移曲线下塑性区面积,由式(4)计算

式中,$b$是韧带的长度,$A_{{\rm pl}}^{{\rm LLD}}$和$A_{{\rm pl}}^{{\rm CMOD}}$分别代表载荷与载荷线位移(load line displacement,LLD)或CMOD曲线下塑性区的面积(见图2)。

图2

3 低约束试件断裂韧性测试关键问题

3.1 应力强度因子

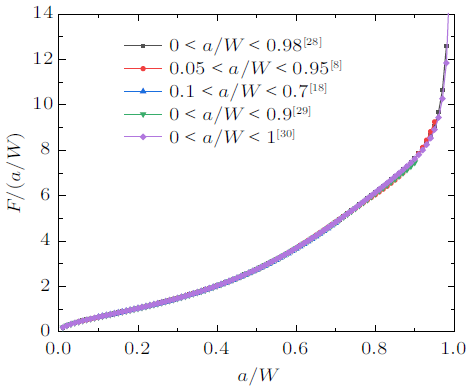

J积分的弹性部分与应力强度因子有关,应力强度因子的准确性对总J积分的计算有直接影响。对于夹持型SENT试件,挪威船级社采用 了Ahmad等[27]提出的应力强度因子解析解。加拿大矿物与能源研究中心通过在弹性和平面应变条件下的有限元计算分析,提出了夹持 型SENT试件应力强度因子的数值解。部分学者先后使用有限元分析法或回归分析法得到应力强度因子不同的计算式,结果对比见 图3,可知各应力强度因子计算方法在其适用范围内基本一致[28-29]。以Zhu[30]提出的应力强度因子全范围解析解为参考,各方法中几何因子的 最大相对误差不超过3% (见图4),而Zhu[30]方法的适用范围更广,精确度较高,建议使用其计算夹持型SENT试件的应力强度因子。

图3

图4

3.2 J积分塑性因子

挪威船级社[16]、加拿大矿物与能源研究中心[7-8]和巴西圣保罗大学[18-19]等先后提出了夹持型SENT试件J积分塑性因子的 不同表达式。2006年,挪威船级社根据三维有限元分析的数值结果,提出了与裂纹深度和试件厚度有关的五阶多项式作为塑性因子评估方 程。Shen等[8]基于Ramberg-Osgood硬化模型,采用平面应变有限元分析,拟合得到塑性因子多项式函数。巴西圣 保罗大学的Cravero等[18]提出塑性因子与应变硬化性能无关理论,并以简单的线性函数表示J积分塑性因子。Mathias等[19]根据巴 西圣保罗大学的数值结果[18,20],通过拟合得到J积分塑性因子的五阶多项式函数。标准BS 8571中J积分塑性因子的计算与试件的厚宽比有关,当试件厚宽比$1≤B/W≤2$时,采用挪威船级社使用的塑性因子方程;当试件厚宽比$1/2≤B/W≤1$时,采用加拿大矿物与能源研究中心使用的塑性因子方程。Huang等[31]和Wang等[32]对有侧槽和无侧槽夹持型SENT试样进行有限元分 析,并提出了与试件裂纹深度、厚宽比以及应变硬化指数有关的J积分塑性因子方程。

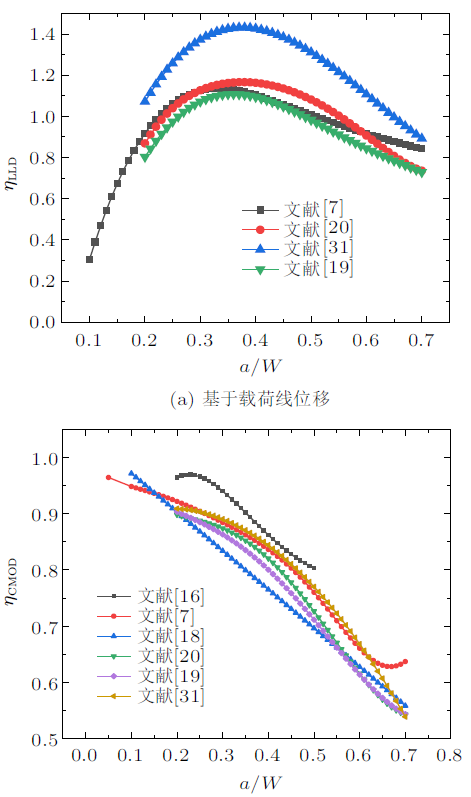

各方法中J积分塑性因子结果对比见图5。对于基于载荷线位移的J积分塑性因子,除Huang方法外,其余三种方法的结果较为接近,而Huang提出 的塑性因子是在考虑试件侧槽的基础上进行的,因而结果偏高;加拿大矿物与能源研究中心提出的塑性因子适用范围更广,建议使用。对于基于裂 纹嘴张开位移的J积分塑性因子,挪威船级社方法明显高于其他方法。巴西圣保罗大 学方法中塑性因子与裂纹深度成线性关系,精度较低,不建议采用;加拿大矿物与能源研究中心方法在$0.05≤a/W≤0.65$范围内建议使用,其余方法在各自的适用范围内偏差较小,而更为精确的J积分塑性因子的表达式有待深入研究。

图5

3.3 J积分与CTOD转换因子

SENT试件的CTOD阻力曲线测试通常可采用J积分转换法或双应变规法。Zhu等[33]采用这两种方法分别对高、低应变硬化性能钢进行测 试,发现采用不同J积分转换因子得到的CTOD阻力曲线不同,而双应变规法测定的CTOD阻力曲线相近。特别是对于高应变硬化钢,两种方法 的CTOD-R曲线明显不同。因而J积分转换因子的准确性对CTOD阻力曲线有直接影响。对于夹持型SENT试件,J积分转换法公式参考标准ASTM E1820,采用式(5)计算

式中,$m$为J积分与CTOD转换因子,$\sigma_{\rm Y}$为屈服强度。

图6

3.4 裂纹尺寸的测量

3.4.1 卸载柔度法

使用单试样法进行断裂韧性测试时,除了测试断裂表征参数,还需测试裂纹扩展长度,常用裂纹长度的测量方法分为卸载柔度法和直流电位梯 度法。卸载柔度法是一种通过监测载荷和裂纹嘴张开位移计算裂纹长度的方法。卸载柔度法在SENB和CT试件断裂韧性测试中已有广泛应用,而 对于低约束SENT试件,Verstraete等[38]通过数值模拟和实验分析证实了卸载柔度法的有效性。不同的测试方法所规定的柔度方程不尽 相同,而如何确定一个相对准确的柔度方程成为了研究的交点。加拿大矿物与能源研究中心、埃克森美孚公司、巴西圣保罗大学、Tyson等均提 出了各自柔度方程。

将上述四个柔度方程与三组独立的有限元计算结果进行比较,发现三组有限元分析结果基本一致,且与加拿大矿物与能源研究中心和巴西圣保罗 大学提出的结果接近,而埃克森美孚公司和Tyson的结果与有限元分析存在明显偏差。因此,目前应使用加拿大矿物与能源研究中心或巴西圣保 罗大学提出的柔度方程。使用卸载柔度法计算裂纹尺寸时,会在初始位置出现裂纹负增长的情况,所以还需参考标准ASTM E1820对初始裂纹尺寸进行修正。

3.4.2 直流电位梯度法

3.5 J积分直接测量技术

2015年,Weeks等[41]采用Prandtl-Reuss增量理论,提出了一种使用表面应变计直接测量夹持型SENT试件J积分的实验方法,结果表明,在裂 纹扩展1 mm范围内直接测量得到的J-R曲线与CANMET法测定的曲线基本一致。2016年,Weeks等[42]对实验技术进行改进,测试了X65管道钢母 材与焊缝的J-R曲线,通过使用数字图像相关技术测量试件的表面应变和远端位移,进而直接计算J积分,结果发现整个实验过程中数字图像相关技术直接测 量的J积分与CANMET方法测试的结果相同。数字图像相关技术可以测试试件表面的整体应变情况,比在表面安装应变计更加可靠,且该方法即不需要使用基 于CMOD的J积分方程,也不需要测量裂纹尺寸的其他装置,因而J积分直接测量技术对于验证基于CMOD的增量J积分方程以及J--R阻力曲线具有重要的意义。

4 结语

断裂韧性是材料的重要性能之一,低约束试件断裂韧性测试对于油气管道安全运营具有重要意义。本文总结了低约束试件的发展历程、断裂韧性表 征参数,分析了测试过程中的关键问题,为低约束试件断裂韧性测试发展提供一定参考。关于低约束试件断裂韧性测试,有以下几方面工作需要 开展更深入研究:

(1) 现有测试方法中J积分塑性因子方程尚未统一,需要通过进一步的有限元计算分析,以确定较为准确的J积分塑性因子表达式。可以利用数字图像相关技术直 接测量J积分技术,验证利用J积分塑性因子计算得到J积分的准确性。

(2) 采用J积分转换法确定CTOD-R阻力曲线时,现有J积分与CTOD转换因子的精确性难以比较,需要进一步通过有限元计算分析,以确定一个更为简 单、准确的J积分与CTOD转换因子表达式。

(3) 部分测试方法要求试件制备侧槽、预制疲劳裂纹,而侧槽形状、侧槽尺寸以及疲劳裂纹前沿曲率对实验结果的影响鲜有研究,需要通过有限元 分析与实验测试结合的方法,量化上述参数的影响,确定较为合理的试件几何模型。

(4) 现有测试方法主要针对均质材料,而对于管道焊缝、热影响区等非均质材料在低约束条件下的断裂韧性测试受匹配系数、焊缝尺寸、热影响区 尺寸等多种因素的影响,需要对各影响因素进行量化,确定非均质材料断裂韧性的测试方法。

(5) 在数值分析和实验验证的基础上,发展我国关于低约束试件断裂韧性测试相关标准。

参考文献

Review of fracture toughness (G, K, J, CTOD, CTOA) testing and standardization

The present paper gives a technical review of fracture toughness testing, evaluation and standardization for metallic materials in terms of the linear elastic fracture mechanics as well as the elastic-plastic fracture mechanics. This includes the early investigations and recent advances of fracture toughness test methods and practices developed by American Society for Testing and Materials (ASTM). The review describes the most important fracture mechanics parameters: the elastic energy release rate G, the stress intensity factor K, the J-integral, the crack-tip opening displacement (CTOD) and the crack-tip opening angle (CTOA) from the basic concept, definition, to experimental estimation, test methods and ASTM standardizing practices. Attention is paid to guidelines on how to choose an appropriate fracture parameter to characterize fracture toughness for the material of interest, and how to measure the fracture toughness value defined either at a critical point or in a resistance curve format using laboratory specimens. The relevant ASTM fracture toughness test standards considered in this paper are E399 for K-lc testing, E561 for K-R curve testing, E813 for J(lc) testing, E1152 for J-R curve testing, E1737 for J(lc) and J-R curve testing, E1290 for CTOD (delta) testing, a combined common test standard E1820 for measuring the three parameters of K, J and delta, E1921 for the transition reference temperature T-0 testing and the master curve of cleavage toughness K-Jc testing, and E2472 for CTOA testing. The effects of loading rate, temperature and crack-tip constraint on fracture toughness as well as fracture instability analysis are also reviewed. (C) 2012 Elsevier Ltd.

基于CTOD/CTOA管道钢断裂韧性测试方法研究进展

高级别管线钢的一大特点是韧度高,导致管材裂纹尖端周围经常处于大范围屈服状态,现有基于高约束试件的断裂韧性测试方法,很难满足新型管材的断裂韧性测试要求. 本文回顾了基于CTOD 和CTOA的断裂韧度参数,详细介绍了管道钢断裂韧性测试方法的研究现状和发展趋势,分析了影响管道钢断裂韧性测试准确性的各种因素,为管道钢断裂韧性的测试提供帮助.

Advances in test methods for fracture toughness based on ctod/ctoa for pipeline steels

管道大范围屈服断裂评估的研究现状与进展

高强度、高韧性管材的大量应用, 提出管道大范围屈服断裂问题. 针对现有的断裂力学方法应用于管道大范围屈服断裂评估的局限性, 分别从双参数断裂力学、基于约束校正的断裂韧性测试、基于应变的断裂评估和基于应变的失效评估图4个方面详细地介绍了管道大范围屈服断裂评估的研究现状. 指出目前基于约束校正的管道断裂韧性测试的主要方法是SENT试件方法和表观断裂韧性方法, 评述了基于SENT试件约束校正的断裂评估研究现状及存在的问题. 阐述了基于应变断裂评估的基本原理, 并从驱动力方程和CTOD失效准则两方面介绍了基于应变的断裂评估方法的研究工作成果. 最后提出了需要进一步研究的问题.

Wang Junqiang, el al. Research status and progress in fracture assessment of pipeline under the condition of large-scale yielding

Review of fracture toughness test methods for ductile materials in low-constraint conditions

Guide to methods for assessing the acceptability of flaws in metallic structures: BS 7910: 2013

Development of procedure for low-constraint toughness testing using a single-specimen technique

Measurement of JR curves using single-specimen technique on clamped SE (T) specimens

Development of the SENT test for strain-based design of welded pipelines

Method of test for determination of fracture toughness in metallic materials using single edge notched tension (SENT) specimens: BS 8571: 2014

Standard test method for measurement of fracture toughness: ASTM E1820-11

New specimen design for plane-strain fracture toughness tests (Sheet specimen design for plane strain fracture toughness tests)

Experimental determination of the dependence of crack extension force on crack length for a single-edge-notch tension specimen

Fracture toughness testing and its applications

The Stress Analysis of Cracks Handbook

Fracture control for pipeline installation methods introducing cyclic plastic strain: DNV-RP-F108

Evaluation of crack growth resistance curves for pipeline steels using constraint designed fracture specimens

Estimation procedure of J-resistance curves for SE (T) fracture specimens using unloading compliance

AbstractThis work provides an estimation procedure to determine J-resistance curves for pin-loaded and clamped SE(T) fracture specimens using the unloading compliance technique and the η-method. A summary of the methodology upon which J and crack extension are derived sets the necessary framework to determine crack resistance data from the measured load vs. displacement curves. The extensive plane-strain analyses enable numerical estimates of the nondimensional compliance, μ, and parameters η and γ for a wide range of specimen geometries and material properties characteristic of structural and pipeline steels. Laboratory testing of an API 5L X60 steel at room temperature using pin-loaded SE(T) specimens with side-grooves provide the load–displacement data needed to validate the estimation procedure for measuring the crack growth resistance curve for the material. The results presented here produce a representative set of solutions which lend further support to develop standard test procedures for constraint-designed SE(T) specimens applicable in measurements of crack growth resistance for pipelines.]]>

Effects of specimen geometry and loading mode on crack growth resistance curves of a high-strength pipeline girth weld

This work presents an investigation of the ductile tearing properties for a girth weld made of an API 5L X80 pipeline steel using experimentally measured crack growth resistance curves. Use of these materials is motivated by the increasing demand in the number of applications for manufacturing high strength pipes for the oil and gas industry including marine applications and steel catenary risers. Testing of the pipeline girth welds employed side-grooved, clamped SE(T) specimens and shallow crack bend SE(B) specimens with a weld centerline notch to determine the crack growth resistance curves based upon the unloading compliance (UC) method using the single specimen technique. Recently developed compliance functions and eta-factors applicable for SE(T) and SE(B) fracture specimens with homogeneous material and overmatched welds are introduced to determine crack growth resistance data from laboratory measurements of load-displacement records. (C) 2013 Elsevier Ltd.

Further results in J and CTOD estimation procedures for SE(T) fracture specimens —— Part I: homogeneous materials

This study provides further developments of the evaluation procedure for J and CTOD in SE(T) fracture specimens based on plastic eta-factors and load separation analysis. Non-linear finite element analyses for plane-strain and 3-D models provide the relationship between plastic work and crack driving forces which define the eta-values. Further analyses based on the load separation method define alternative eta-values for the analyzed specimen configurations. Overall, the present results provide improved estimation equations for J and CTOD as a function of loading condition (pin load vs. clamp ends), crack geometry and strain hardening properties. (C) 2011 Elsevier Ltd.

UGent guidelines for SENT testing

Determination of tearing resistance in SENT and CWP specimens using direct current potential drop measurement

Determination of CTOD resistance curves in side-grooved Single-Edge Notched Tensile specimens using full field deformation measurements

The experimental evaluation of fracture toughness of linepipe steels is increasingly performed through Single Edge Notched Tensile (SENT) testing. The notch constraint in these specimens closely matches that in pipes. This article explores the possibilities of using full field deformation and strain measurements during SENT testing. Based on the obtained deformation fields, the Crack Tip Opening Displacement (CTOD) has successfully been evaluated. In addition, the deformation near the cracked ligament allows estimating the amount of ductile crack extension for shallow notched specimens. The combination of both allows constructing resistance curves for the tested materials. (C) 2013 Elsevier Ltd.

Application of fracture mechanics at and beyond general yielding

Evaluation and comparison of double clip gauge method and delta 5 method for CTOD measurement in SE (T) specimens

A path independent integral and the approximate analysis of strain concentration by notches and cracks

Elastic-plastic analysis of edge-notched panels subjected to fixed grip loading

Corrected stress intensity factor solution for a British standard single edge notched tension (SENT) specimen

Effect of height to width ratio on K and CMOD solutions for a single edge cracked geometry with clamped ends

Full-range stress intensity factor solutions for clamped SENT specimens

Investigation of plastic eta factors for clamped SE (T) specimens based on three-dimensional finite element analyses

A complementary ƞpl approach in J and CTOD estimations for clamped SENT specimens

Comparative study of CTOD-resistance curve test methods for SENT specimens

J-CTOD relationship for clamped SE (T) specimens based on three-dimensional finite element analyses

Estimation procedures for J and CTOD fracture parameters experimental evaluation using homogeneous and mismatched clamped SE (T) specimens

Low constraint fracture toughness testing using SE (T) and SE (B) specimens

Relationship between J and CTOD in SE (T) and SE (B) specimens for stationary and growing cracks

Evaluation and interpretation of ductile crack extension in SENT specimens using unloading compliance technique

Resistance curves obtained from Single Edge Notch Tensile (SENT) specimens gain interest for defect assessment in pipelines. To determine these resistance curves, the unloading compliance technique is a commonly applied single specimen technique. A frequently reported problem is the occurrence of an initial decrease in the compliance, resulting in an apparent negative crack growth. To overcome this problem an offset in combination with a blunting correction is proposed. This approach is evaluated by finite element simulations. Then the proposed approach is validated experimentally. The presented approach is simple in use and provides an acceptable estimation error when it comes to constructing resistance curves. (C) 2013 Elsevier Ltd.

Review and applications of the electric potential method for measuring crack growth in specimens, flawed pipes, and pressure vessels

Using DC electric potential for crack initiation/growth monitoring during testing of weld metal fracture specimens

Comparison of J-integral from single specimen SE (T) tests on API-5L X100 line pipe steel

Comparison of J-integral measurement methods on clamped single-edge notched tension specimens